-

You have no items in your shopping cart.

- Register

- Log in

- Wishlist

- Shopping cart

Write your own review

Reviews

Easy for me to adjust as needed

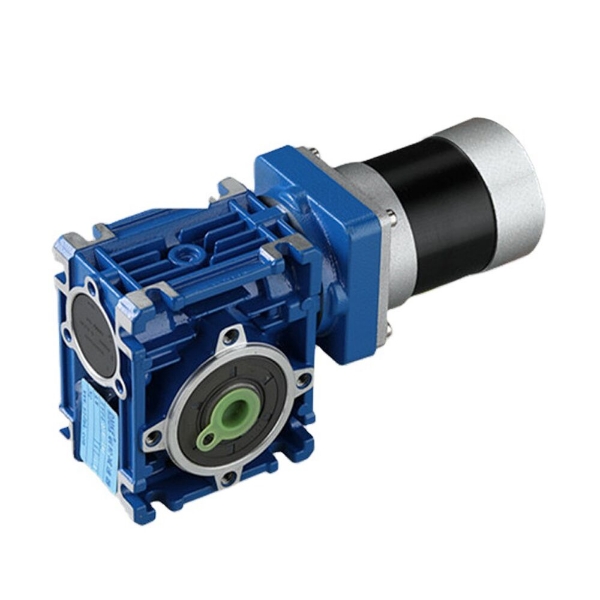

This BLDC worm gear motor is perfect for the high power applications I need, and the two voltage options of 24V and 48V make it easy for me to adjust as needed."

Johnson

|

10/27/2023 3:07 AM

Was this review helpful?

(0/0)