Close

-

You have no items in your shopping cart.

- Register

- Log in

- Wishlist

- Shopping cart

Close

- Home /

- Brushless Gear Motors /

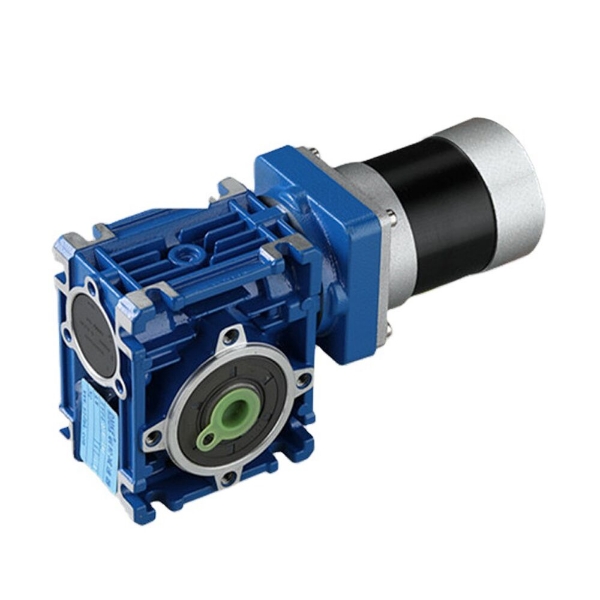

- BLDC Worm Gear Motor /

- 200W BLDC Worm Gear Motor, 12V/ 24V/ 48V

Write your own review

Related products

50W BLDC Worm Gear Motor, 12V/ 24V

BLDC-GEAR-W50

50W DC worm gear motor for sale at an affordable price. High torque worm gear motor works with 2000 rpm rated speed and 0.16 Nm rated torque, selectable 12V, 24V or 36V power supply, gear ratio from 7.5:1 to 60:1. 3-phase 12V/ 24V worm gear motor has high performance, low energy consumption, low noise, small vibration, lightweight and easy to reverse.

$459.36

100W BLDC Worm Gear Motor, 12V/ 24V/ 48V

BLDC-GEAR-W100

Lower cost 100W DC worm gear motor with optional power supply 12V/ 24V/ 36V/ 48V, 3-phase worm gear motor features 2000 rpm rated speed, rated torque at 0.32 Nm and peak torque at 0.96 Nm, gear ratio from 7.5:1 to 80:1. The gear motor with all-metal gears, high-temperature resistance, high abrasion resistance, strong load capacity, sturdy and durable, effectively protect the turbo worm gear box motor body.

$484.27

450W BLDC Worm Gear Motor, 12V/ 24V/ 48V

BLDC-GEAR-W450

High performance BLDC worm gear motor with cheap price online for sale. High torque 450W DC worm gear motor has selectable power supply of 12V, 24V, 36V, 48V, and gear ratio from 7.5:1 to 100:1 can be chosen, low speed at 2000 rpm, rated torque 1.43 Nm, motor dimension 86mm. BLDC motor with worm gearbox used for electric car, renewable energy systems and industrial equipment.

$709.66

600W BLDC Worm Gear Motor, 24V/ 48V

BLDC-GEAR-W600

High quality 600W DC worm gear motor with optional gear ratio from 7.5:1 to 100:1, features 2000 rpm rated speed at 24V, 36V/ 48V, high torque at 1.91 Nm and peak torque can up to 5.73 Nm. The shell of dc worm gear motor is made of aluminum alloy and has the advantages of light weight, superior strength, high heat dissipation performance, long service life, and no noise.

$759.88

BLDC Motors - Combine Durability, Efficiency, and Customization for High Performance.

Resource

Customer service

Powered by Brushless.com

Copyright © 2026 Brushless.com. All rights reserved.