In the medical field, precision, reliability, and miniaturization are non-negotiable. From surgical robotics to diagnostic imaging systems, every component inside a medical device must be optimized to deliver consistent performance while meeting strict safety and regulatory standards. Among the most critical components are the motors that drive motion. Frameless brushless motors are increasingly becoming the preferred choice in medical applications due to their efficiency, compact design, and ability to integrate seamlessly into custom assemblies.

What Are Frameless Brushless Motors?

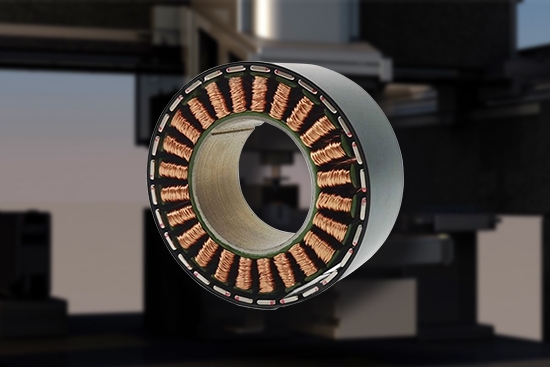

Frameless brushless motors consist of only two core components: the rotor and the stator. Unlike conventional housed motors, they do not include an external casing, shaft, or bearings. This frameless construction allows engineers to directly integrate the motor into their mechanical system, reducing size and weight while maximizing flexibility in design.

For medical device manufacturers, this architecture provides unique advantages, enabling more compact systems and smoother operation in highly sensitive environments.

Advantages of Frameless Brushless Motors in Medical Devices

The medical industry demands components that combine reliability, precision, and adaptability. Frameless brushless motors meet these requirements by offering a unique balance of compact design, energy efficiency, and advanced motion control. Unlike traditional housed motors, their frameless architecture gives engineers the flexibility to integrate customized solutions directly into medical equipment. The following key advantages highlight why frameless brushless motors are increasingly adopted in surgical, diagnostic, and therapeutic devices.

Compact Integration for Miniaturized Devices

Modern medical technology demands increasingly smaller devices without sacrificing performance. Frameless brushless motors allow for direct integration into custom housings, enabling medical equipment designers to minimize space usage. This is particularly beneficial in handheld tools such as surgical drills or dental instruments, where every millimeter counts.

High Efficiency and Low Heat Generation

In applications like robotic surgery or diagnostic scanners, thermal management is critical. Excessive heat can affect device accuracy or patient comfort. Frameless brushless motors are highly efficient, converting electrical energy into mechanical motion with minimal losses. Their low heat output ensures stable operation, even during prolonged procedures.

Precision Motion Control

Medical devices often require precise, smooth, and quiet motion. Frameless brushless motors, when paired with advanced control electronics, deliver accurate torque and speed control with minimal vibration. This precision is crucial for robotic surgical systems, where even micrometer-level accuracy can impact patient outcomes.

Reliability and Long Service Life

Because they lack brushes and commutators, frameless brushless motors exhibit low wear and tear and require minimal maintenance. In medical environments where downtime can compromise patient safety, the reliability of brushless technology ensures long service life and reduced risk of unexpected failure.

Flexibility in Design and Customization

Each medical device has unique mechanical and performance requirements. Frameless DC motors provide the flexibility to customize winding configurations, mounting methods, and sensor integration. This adaptability allows engineers to optimize performance for applications ranging from portable infusion pumps to large imaging equipment.

Quiet Operation for Patient Comfort

Noise reduction is another key factor in medical environments. Whether used in imaging systems or therapeutic equipment, frameless brushless motors operate quietly, reducing patient stress and contributing to a more comfortable healthcare experience.

Applications of Frameless Brushless Motors in the Medical Industry

- Robotic Surgical Systems: Frameless brushless motors deliver the high precision, smooth motion, and torque control required for robotic-assisted surgeries. Their compact form factor enables integration into robotic arms and end-effectors, allowing surgeons to perform minimally invasive procedures with greater accuracy, reduced fatigue, and enhanced patient outcomes.

- Diagnostic Imaging Equipment: In CT and MRI scanners, frameless DC brushless motors ensure stable and reliable gantry rotation, critical for producing high-resolution images. Their low vibration and quiet operation help maintain image clarity while improving patient comfort during long scans.

- Handheld Surgical Tools: From surgical drills to dental instruments, frameless brushless motors provide lightweight and ergonomic designs without sacrificing power. Their high torque density enables efficient tissue cutting and bone drilling, while low heat generation ensures safety during extended use in sensitive procedures.

- Laboratory Automation: Frameless brushless motors play a central role in automated lab equipment such as pipetting systems, sample handlers, and centrifuges. Their accurate and repeatable motion control supports high-throughput testing, reduces human error, and increases the overall efficiency of modern clinical laboratories.

Infusion and Pump Systems: Reliable drug delivery requires precise flow control. Frameless brushless motors offer consistent performance for infusion pumps, dialysis machines, and other therapeutic devices. Their durability and low maintenance needs make them ideal for continuous operation in critical care environments.

Frameless brushless motors are driving innovation in the medical industry by offering unmatched precision, efficiency, and design flexibility. Their ability to integrate seamlessly into compact devices makes them indispensable in applications ranging from surgical robotics to diagnostic imaging. A specialized brushless motor shop provides access to high-quality components, engineering expertise, and tailored designs that help medical devices meet the strict requirements of modern healthcare technology.