The EPS system's operating logic can be simplified as "signal acquisition → ECU decision → motor execution": Sensors collect real-time steering wheel torque and vehicle speed data. The ECU calculates the required assist torque, which then drives the brushless motor to output power, which is ultimately transmitted to the steering mechanism via a reduction gear. During this process, the brushless motor's "output" relies on high current, and this high current is the core factor that causes elevated motor temperature.

From a system safety perspective, excessively high brushless motor temperatures pose two major risks:

Aging of the motor winding insulation: When temperatures exceed 125°C (a common industry threshold), the winding insulation performance degrades dramatically, potentially leading to short circuits and burnout.

Magnet demagnetization: Permanent magnets lose their magnetic permeability at high temperatures, reducing motor output torque and directly impacting EPS performance and even causing steering failure.

To gain a deeper understanding of the technological development of brushless motors in high-temperature, high-reliability environments, Brushless is a one-stop online store that offers brushless DC motors (BLDCs), motor controllers, gearboxes, and other products, covering a wide range of aspects. Brushless covers a wide range of aspects, from motor design and material selection to thermal management strategies, providing engineers with systematic solutions.

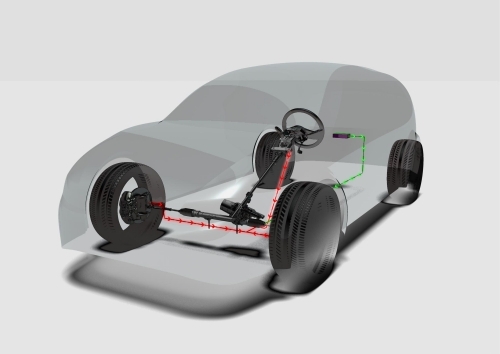

Working Principles of EPS Systems and Brushless Motors

The electric power steering system uses the ECU (Control Unit) to accurately calculate and control the motor to provide appropriate assist based on information such as hand torque and vehicle speed collected by sensors. As the actuator of the EPS system, the brushless motor is characterized by high efficiency, long life, and low noise, but it generates significant heat when operating at high currents.

Mechanisms of the EPS System's Impact on Brushless Motor Temperature

Current-Temperature Relationship

When the EPS system is operating, the temperature increase of the brushless motor is primarily due to heat generated by copper and iron losses. Higher current increases copper losses (I²R), and thus, more heat is generated. Research has shown that motor temperature is positively correlated with input current, especially under long-term, high-load operating conditions.

Temperature Cumulative Effect

The increase in motor temperature is a cumulative process, closely related not only to the current operating current but also to historical operating conditions and ambient temperature. Chen Jin and Qian Weikang proposed that distinguishing between rapid and slow heating models during control can more accurately estimate the system temperature increase. The rapid heating model reflects the temperature response to sudden current changes, while the slow heating model describes temperature changes under steady-state operating conditions.

Impact of Environmental Factors

In addition to operating current, factors such as ambient temperature, heat dissipation conditions, and motor mounting position also affect brushless motor temperature. In high-temperature environments, the motor's heat dissipation efficiency decreases, making overheating more likely.

Brushless Motor Temperature Estimation and Thermal Management Strategy

Temperature Estimation Method

Accurately estimating motor temperature is a prerequisite for effective thermal management. This research proposes a temperature estimation method based on a thermal model. By establishing fast and slow thermal models, the system temperature increase is calculated. Combined with parameters such as current temperature and input current, this method enables real-time estimation of motor temperature. This method not only considers the instantaneous impact of current but also the cumulative effect of temperature, improving estimation accuracy.

Thermal Protection Strategy

Based on the temperature estimation results, a corresponding thermal protection strategy can be designed. When the estimated temperature approaches or exceeds a safety threshold, the system can take the following actions:

- Limiting motor output current to reduce heat generation

- Initiating forced cooling measures, such as fan cooling

- In extreme cases, temporarily disabling the power assist function to protect the motor and system safety

Thermal Management Optimization

By optimizing control algorithms and heat dissipation design, motor temperature can be effectively controlled while maintaining system performance. Simulations and experiments in this research demonstrate that this thermal management analysis and design approach successfully balances system cost and safety.

To address the challenges of heat buildup and performance stability, engineers often employ brushless DC motors designed with an outer rotor configuration. Such motors combine high power density with efficient heat dissipation, ensuring stable operation in high-temperature and complex environments. Their broad speed control range, along with optional Hall sensors and integrated gear reduction, makes them well-suited for EPS systems, industrial automation, robotics, and CNC machine tools, where reliability and durability are paramount.

Ensuring the thermal stability of brushless motors is fundamental to the safety and reliability of EPS systems. Accurate temperature estimation and well-designed protection strategies help prevent insulation aging and magnet demagnetization, while the use of outer rotor BLDC motors offers enhanced heat dissipation and operational stability. Together, these approaches provide a practical path toward maintaining high performance under demanding conditions.