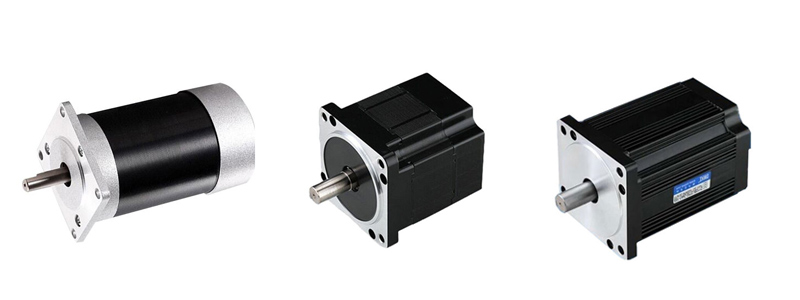

Brushless DC motors are widely used in AI intelligence, automobiles, medical equipment, industrial automation, etc. due to their long life, low noise, and high torque. Because of their different specifications and types, the right brushless DC motors are selected to meet product performance requirements, which is very important. So how do we choose a BLDC motor that is most suitable for our products?

Principles of choosing a brushless DC motor

- The motor that is most suitable for these characteristics must be selected according to the production machinery's load, starting characteristics and operating characteristics to meet the machine's various requirements during the working process.

- Select a brushless motor with a protection method and cooling method that is suitable for the user's use environment, so that the motor can exert better efficiency.

- Calculate and determine the appropriate motor power. Usually, when the motor is designed and manufactured, the efficiency is the highest at 75%-100% of the rated load. Therefore, the difference between the rated power required by the product and the rated power of the motor used is the smallest, so that the power of the motor can be fully utilized so that both high efficiency and energy saving can be achieved. 50W~3.8kW brushless DC motors are available on Brushless.com.

- Choose a motor that is easy to maintain. The entire motor casing is easy to disassemble, which is convenient for maintenance and saves time.

- Considering the interchangeability, try to choose a standard motor. If the product pursues differentiation, it can also be customized after determining the parameters.

- The speed, number of poles, voltage and kV value of the motor should be comprehensively considered. High-efficiency 12V, 24V, and 36V brushless DC motors are provided.

Selection steps of BLDC motor on Brushless.com

- According to the requirements of the equipment, determine the load power of the equipment when the user is using it, the normal current and the maximum current during operation, etc.

- Fully consider the use environment and state of the product, determine the power supply, and then determine the rated voltage and working voltage range of the motor.

- Determine the number of revolutions of the brushless DC motor according to the number of revolutions required by the equipment, the transmission device and the gearbox. The 3 phase 12V BLDC motor has a rated speed of 3000, 24V and 36V are the same.

- According to the installation location and use environment of the motor and mechanical equipment, determine the structure and protection from the brushless motor, as well as the working temperature and humidity range of the brushless motor.

- Determine the rated power and maximum power of the brushless motor according to the power required by the load and the operation mode of the motor.

- The 50W~1500W brushless DC motor needs to be equipped with a high-efficiency drive controller to ensure that the motor can work with maximum efficiency.

The most important point is that you must also match the most suitable motor drive controller for the brushless motor you choose.

The choice of a 12V, 24V, or 36V brushless motor controller is also related to the efficiency and the working state of the motor. Selecting a suitable brushless motor is only the first step. Later, you need to set parameters, protection settings, and function settings according to your product, and these all require a brushless motor controller to do the best design according to your product.

Brushless.com has been focusing on brushless motor controllers for 5 years. With rich practical experience and innovative technology, it can quickly meet your new product development needs and provide personalized BLDC motors solutions.