Brushless DC motors have been widely used in various fields today because of the advantages of simple structure, reliable operation and easy maintenance of AC motors, as well as the advantages of high efficiency, no excitation loss and good speed regulation performance of DC motors.

The stator of a brushless DC motor is a coil-wound armature and the rotor is a permanent magnet. If only a fixed DC current is passed to the motor, the motor can only produce a constant magnetic field and cannot turn up. The motor can only run with the magnetic field if the rotor position is detected and the corresponding current is switched on to the motor according to the rotor.

The wiring principle of the general brushless DC motor is basically similar. Here we take a 24V brushless motor as an example to show you how to connect the motor to the controller and make the motor turn.

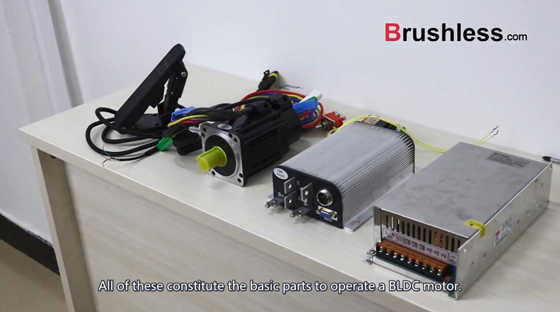

To test 24V BLDC motor requires a controller, 24V DC power supply start switch, a push button switch & a toggle switch, including power wires and hall wires, as well as a resistive accelerator pedal. All of these constitute the basic parts to operate a BLDC motor.

Wiring and Testing Steps

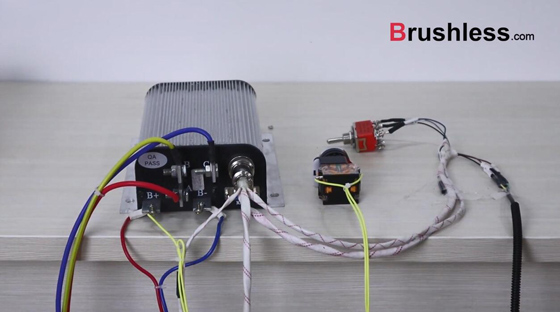

- To begin with, we’d connect the power wires and hall wires separately. As to power wires, the red, yellow and blue wires are supposed to be connected to the output terminals A, B and C of the motor controller.

- Plug the hall wires into the controller.

- Connect B+ and B- to 24V+ and 0V (COM) terminals on the power supply.

- The power control wire 1 PWR needs to be connected to a 24V+ port. And we’ll use a self-locking button switch for control.

- Join No.2, 9 and 8 leads to the toggle switch.

- No.2 (3), 5 & 7 wires are meant to be connected to the accelerator pedal.

Startup Sequence

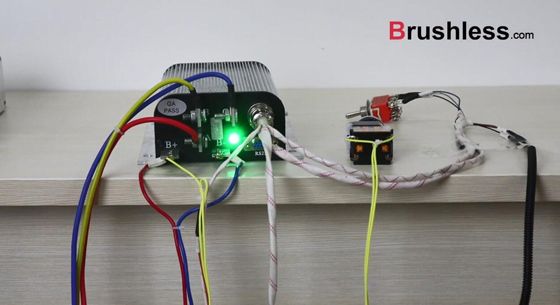

- Press the button switch to connect line 1 and 24V.

- Switch the rotation direction of the motor.

- Depress the accelerator pedal.

- Depress the accelerator pedal to make the motor spin.

- Switch the rotation direction to let the motor rotate in reverse.

That’s all for the wiring and operation demo. You can watch the video below for more detailed wiring instructions. This video shows how to wire and operate a 24V brushless DC motor that is designed to be used for motor racing and industrial automation. In addition, 48V, 72V, and 96V brushless motors are also available on Brushless.com.