An electronic speed controller is a device that is widely used in a variety of electric motors and drive systems, and its main function is to adjust and control the operating speed of the motor. This type of controller uses advanced electronic technology to monitor, compare, and adjust the output of the motor to achieve accurate and reliable speed control. The following is a detailed description of electronic speed controllers from the Brushless shop.

Basic Principle

The basic principle of an electronic speed controller is to change the speed of a motor by adjusting the voltage or current supplied to the motor. This is usually accomplished by adjusting the input voltage or current to the motor. Electronic speed controllers utilize advanced electronic components such as programmable logic controllers (PLCs), frequency inverters, and digital signal processors (DSPs) to monitor the motor's operating status in real-time and make adjustments based on preset parameters.

The electronic speed controller can be used in open-loop control or closed-loop control mode. In open-loop control, the system directly controls the output of the motor according to the input set value. In closed-loop control, on the other hand, the system monitors the motor's speed or position in real-time using sensors and feeds this information back to the controller for more precise control.

Structural Components

- Input Circuitry: Input circuitry receives external signals, usually supplied by the user or an automated control system. This part includes the speed setter, which adjusts the operating speed of the motor by setting the desired speed. The speed setter can be a knob, digital input, or other type of control device.

- Speed Measuring Element: To implement closed-loop feedback control, electronic speed controllers are usually equipped with a speed measuring element, such as an encoder or Hall sensor. The speed element is used to monitor the current operating speed of the motor and feeds actual speed information back to the controller so that the motor inputs can be adjusted to maintain the desired speed.

- Control Circuit: The control circuit is the core part of the electronic speed controller and generates a control signal based on the difference between the actual speed and the desired speed. This signal is amplified and processed and then passed to the motor through the output circuit to adjust the motor speed. The control circuit is usually designed with a Proportional Integral Derivative (PID) control algorithm to ensure system stability and responsiveness.

- Output Circuitry: The output circuitry converts the control signals into appropriate voltages and currents to be supplied to the motor drive section. This may involve a power amplifier or inverter, depending on the type of motor and drive requirements.

- Power Supply: Electronic speed controllers require a stable power supply to provide the required power to the various sections. The power supply is usually a DC power source, but it is possible to convert an AC power source to a DC power source using a suitable converter.

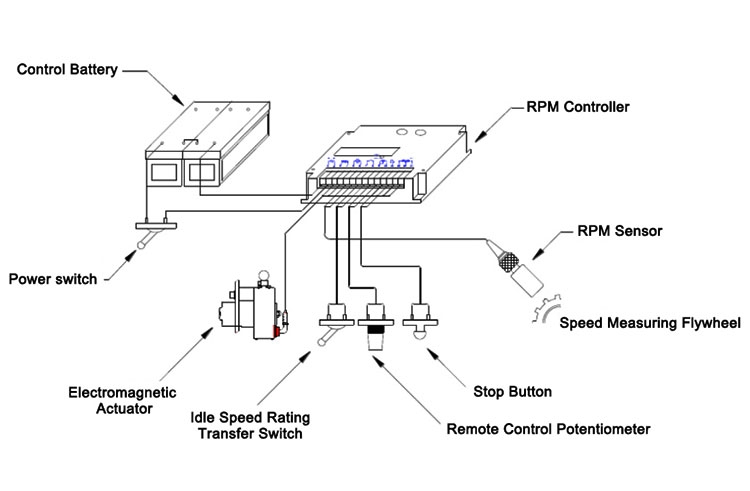

Principle of Operation of Electronic Speed Controller

The ideal speed of the engine is set by the speed setting potentiometer and the speed trimming potentiometer, and the actual speed of the engine is sensed by the speed sensor installed in the root part of the flywheel teeth, and the output signal of the speed sensor is an AC voltage signal whose frequency and speed are proportional to each other. The signal is converted to DC voltage by the circuit and speed set value after a comparison of the speed deviation.

The deviation is amplified by the regulator arithmetic to derive the position value of the fuel supply, that is, the actuator's steady-state output position command, the position command and the electromagnetic actuator with the comparison of the actual position value, to get the actual position of the deviation, the deviation is amplified by the regulator arithmetic, converted into a current control mode to the electromagnetic actuator The deviation is then converted into current control mode to output drive current to electromagnetic actuator, thus changing the motion displacement of electromagnetic actuator.

Advantages of Electronic Speed Controller

First of all, an electronic speed controller can provide more accurate speed control. Through the use of advanced electronic components and algorithms, precise regulation of motor speed can be realized to meet the precision requirements of different applications. This is important for systems that require a high degree of controllability and precision, such as industrial production lines or precision instruments.

Secondly, electronic speed controllers have better dynamic response performance. Compared to the inertia and hysteresis of mechanical speed control systems, electronic controls can respond faster to changes and quickly adjust the motor's operating state. This makes the system more flexible to adapt to different operating conditions and load changes.

In addition, electronic speed controllers allow for energy efficiency optimization. Designed to be applied to brushless motor controllers, electronic speed controllers can maximize energy efficiency, reduce energy consumption, and lower operating costs by intelligently adjusting the motor's operating parameters, such as current and voltage, with electronic control. This is crucial for modern industries that are pursuing sustainable development and energy conservation.

Finally, electronic speed controllers offer more functional integration. They are often equipped with various protection and monitoring features, such as overload protection, temperature monitoring, etc., to ensure that the motor operates within safe limits. In addition, some advanced electronic speed controllers support communication interfaces, enabling them to be integrated with other systems for intelligent remote monitoring and control.

Application Areas of Electronic Speed Controllers

- Manufacturing Industry: Electronic speed controllers are widely used in a variety of equipment on production lines, such as machine tools, conveyor belts, and packaging machinery. By accurately controlling the motor speed, productivity can be improved, energy consumption can be reduced, and a high-quality production process can be realized.

- Transportation: Electronic speed controllers are used in automobiles, electric vehicles, and railroad transportation systems. These controllers not only provide smooth speed regulation, but also improve the efficiency of traffic flow, slow down wear and tear, and increase the reliability of the overall transportation system through intelligent control systems.

- Energy Sector: Electronic speed controllers are widely used in wind turbines and solar tracking systems. By accurately controlling the rotational speed of wind turbines or the tilt angle of solar panels, energy output can be maximized and the efficiency of renewable energy use can be improved.

- Medical Equipment: Electronic speed controllers are used in precision instruments, medical robots, and medical infusion pumps. Their highly adjustable performance enables these devices to perform tasks with greater precision, improving the accuracy and safety of medical operations.

- Aerospace: Electronic speed controllers are used in aircraft engines, spacecraft attitude control, and unmanned aircraft systems. These applications require highly reliable speed regulation to ensure that the vehicle remains stable in a variety of environmental conditions.

As a key power electronic device, high precision electronic speed controllers play an important role in modern industrial and technological applications. By providing precise speed control and efficient energy utilization, electronic speed controllers play a key role in a wide range of fields such as manufacturing, transportation, energy, medical, and aerospace, driving innovation and upgrading of electric motor drive systems, bringing greater productivity and sustainability to all sectors.