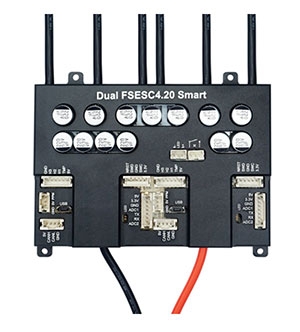

Electronic speed controllers are a key device that is widely used in motor systems to achieve efficient and precise control of motor speed through the use of advanced electronics and control algorithms. In this article, Brushless Store will take a closer look at how electronic speed controllers work, and the electronic speed controller prospects.

Electronic Speed Controllers Working Principle

The working principle of electronic speed controllers is based on pulse width modulation (PWM) technology, which is a method of controlling levels by periodically switching the current on and off. Here are the main steps in how an electronic speed controller works.

- Sensor Feedback: Electronic speed controllers are usually equipped with sensors to monitor the operating status of the motor, such as speed, current, and temperature. These sensors enable the system to adjust the motor's operating parameters in real-time by feeding information about the actual operating state back to the control system.

- Control Algorithms: Electronic speed controllers are equipped with advanced control algorithms that are responsible for calculating the control signals that should be applied based on the data fed back from the sensors. These signals determine the current and voltage waveforms required by the motor to achieve the desired speed regulation.

- PWM Modulation: Through the use of PWM technology, electronic speed controllers switch the current on and off periodically for short periods. By adjusting the duty cycle of the current (i.e., the ratio of the high level to the total period), the controller enables regulation of the average motor current. This modulation is one of the key factors that make electronic speed controllers more efficient than conventional methods.

- Power Electronic Switches: Electronic speed controllers contain power electronic switches that are responsible for turning the current path on and off at different points in time. The operation of these switches is determined by a combination of control algorithms and PWM signals to ensure precise speed control of the motor.

- Motor Response: BLDC motors adjust accordingly to the current and voltage signals provided by the electronic speed controller to achieve the desired speed. Due to the high efficiency of PWM technology, the controller can respond quickly to changes, making the motor's operation very flexible and stable.

Electronic Speed Controller Working Mode

An electronic speed controller is a kind of advanced power electronic device, which realizes the control of motor speed by precisely regulating the current and voltage of the motor. Its working mode is mainly divided into two kinds open-loop control and closed-loop control.

Open-loop Control: In open-loop control, the electronic speed controller directly outputs the corresponding current and voltage signals according to the pre-set speed command without real-time feedback of the actual running status of the motor. This method is simple and direct and is suitable for some relatively simple application scenarios that do not require high speed. However, open-loop control cannot actively correct for external disturbances or load changes, so it may not be ideal for applications that require precise control.

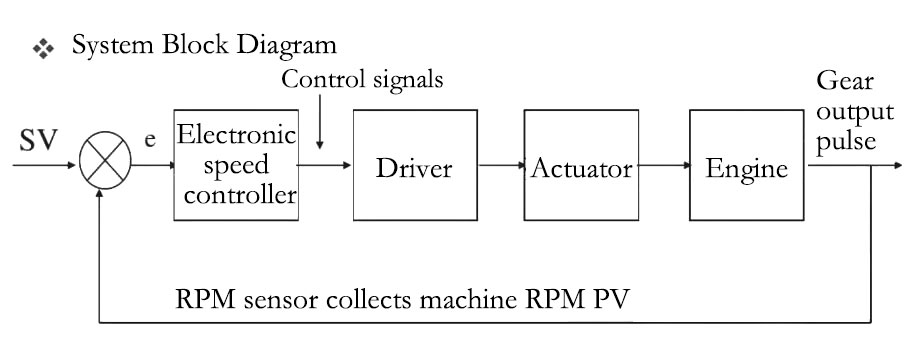

Closed-loop Control: Closed-loop control is a more sophisticated way of working with electronic speed controllers. It monitors the running status of the motor in real-time through sensors and feeds the actual running data back to the control system. The control algorithm compares the differences between the actual operating state and the desired state and adjusts the output signal according to these differences to bring the motor up to the desired speed. Closed-loop control can more accurately regulate the speed of the motor and is suitable for applications that require high-speed accuracy, such as precision instruments and automated production lines.

Working Process of Electronic Speed Controller

An electronic speed controller is a key power electronic device that is mainly used to regulate the speed of an electric motor. Its working process is a complex and efficient system involving real-time monitoring of sensors, calculation of control algorithms, application of PWM technology, and operation of power electronic switches.

First, the working process starts with setting the target speed. The user or the system sets the desired motor speed and this target speed will be the reference for the control system. Next, the electronic speed controller monitors the motor's operating status in real-time through built-in sensors. These sensors include speed sensors, current sensors, and temperature sensors. By continuously acquiring these parameters, the controller can understand the current actual operating status of the motor.

The data obtained from the sensors is transmitted to the control algorithm, which is the core of the electronic speed controller. The control algorithm calculates the control signal that should be applied by comparing the difference between the actual operating state and the set target speed. This algorithm typically uses a closed-loop control system that can dynamically adjust the control strategy based on real-time feedback.

The control signal generated by the control algorithm is then modulated by pulse width modulation (PWM), a method of regulating the average motor current by periodically switching the current on and off. By adjusting the duty cycle of the current, i.e., the ratio of the high level to the total period, the controller can achieve accurate regulation of the average current of the motor. These PWM signals are passed to internal power electronic switches that are responsible for turning the current path on or off at different points in time. The operation of the power electronic switches is determined by both the control algorithm and the PWM signals to ensure that the motor receives accurate speed control.

Finally, the motor adjusts itself according to the control signals so that the actual speed gradually converges to the target speed. This adjustment process is an iterative process, through continuous monitoring, comparison, and adjustment, the electronic speed controller can keep the motor running stably within the desired speed range.

The whole working process can be summarized as follows, the sensor monitors the motor status, the control algorithm calculates the control signals, the PWM technology modulates the signals, the power electronic switch operates, and the motor responds to the adjustments, thus realizing efficient and precise control of the motor speed. The working process of the electronic speed controller is characterized by a high degree of automation and intelligence, which makes it capable of handling different work requirements in various applications. The high efficiency and precision of this process is the reason why electronic speed controllers have become one of the key indispensable technologies in modern motor drive systems.

Future Prospects for Electronic Speed Controllers

- Intelligent and Adaptive Control: Future the best quality electronic speed controllers will be more intelligent, able to adaptively adjust the control strategy according to the environmental conditions and load changes to improve the flexibility and adaptability of the system.

- Integrated and Modular Design: Future electronic speed controllers may tend to be more compact and modular in design to accommodate different sizes and types of applications and improve equipment integration.

- Energy-efficiency Optimization and Green Technology: With the increasing concern for energy sustainability and environmental protection, future electronic speed controllers will pay more attention to energy-efficiency optimization, adopt more environmentally friendly technologies, and push motor systems to develop in the direction of lower power consumption and greener.

- High-performance Computing and Communication Technologies: Future electronic speed controllers may make greater use of high-performance computing and advanced communication technologies to achieve tighter integration with other systems and higher levels of automation and intelligence.

- New Sensing Technology: With the continuous progress of sensing technology, future electronic speed controllers may use more advanced sensors to provide more accurate, real-time motor operating state information, further improving the accuracy of control.

The application of electronic speed controllers in the field of industry science and technology has a very broad prospect. Its continuous innovation and upgrading will promote the development of motor systems, making them more intelligent, efficient, and sustainable. As a key component of the motor system, electronic speed controllers will continue to play an important role in promoting industrial and technological progress.