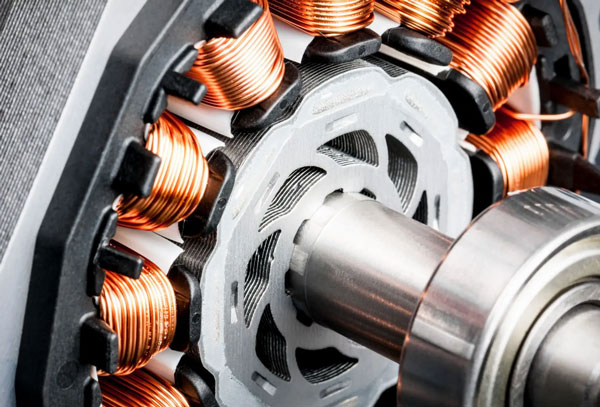

Due to the large-scale research and development of brushless DC motors and the gradual maturity of technology, the distribution of its drive system in industrial production has expanded and has gradually become the mainstream of industrial motor development, and major manufacturers also provide different models of brushless motors to meet the needs of different drive systems. At present, brushless motors are used in textile, metallurgy, printing, automated production lines, CNC machine tools, and other industrial production.

Fixed speed drive machinery

General industrial occasions do not require speed regulation in the field of most of the past is the use of three-phase or single-phase AC asynchronous and synchronous motors.

- Single direction continuous operation of the load mostly using AC asynchronous motors, such as pumps, fans, compressors, etc. choose the appropriate speed of 2 or 4-pole asynchronous motor.

- For the requirements of small size, lightweight, and high working speed, such as higher than 3000r/min load such as agitator, vacuum cleaner and carpet cleaning and washing machine, etc., then more single-phase series-excited motor or brushless DC motor directly drive the load, for the requirements of less noise high-speed drive, can consider the use of inverter-powered medium frequency asynchronous motor or DC-powered brushless DC motor.

- For small work machinery with smaller power and larger speed, inexpensive asynchronous motors can be used.

- For low-speed working machinery, especially frequent forward and reverse adjustment, in order to shorten the transition process time, improve production efficiency and reduce noise, the low-speed direct drive can be used, choose low-speed electromagnetic reduction synchronous motor or gear reduction asynchronous motor, such as automatic doors and high power mixers, etc.

Speed-controlled drive machinery

Speed needs to be set and adjusted arbitrarily, one is the open-loop speed control system, and the other is a closed-loop speed control system, usually using three main motors: DC motors, AC asynchronous motors, and brushless DC motors. Such as packaging machinery. Food machinery, printing machinery, material handling machinery, textile machinery, and traffic vehicles have a large number of applications. In all industrial systems, where everything needs high speed, most of the current brushless DC motor servo control systems. Brushless DC motor as the servo motor, the early application of multiple occasions is the CNC machine tools, the production of CNC machine tools, the use of CNC brushless DC motor, making the speed of the equipment greatly improved, the speed of production efficiency. For example. High-speed punching machine punching speed can reach 800 times per minute, the general operating speed is 400 times per minute.