As the saying goes, "If you want to do a good job, you must first sharpen your tool." As a mechanical component, the electric screwdriver cannot work normally without the electric batch power supply. The electric batch power supply provides energy and related control functions for the electric screwdriver. drive the rotation of the motor. Due to the different parameters of the electric screwdriver motor, the speed will be different when the electric batch power supply outputs the same power.

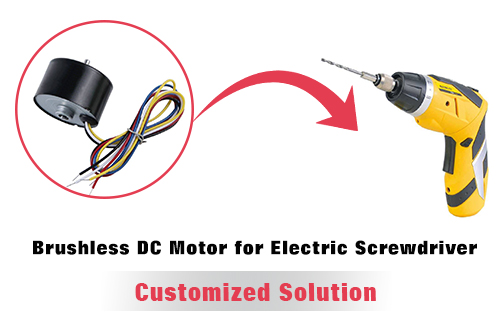

BLDC-24V-6000R high-speed brushless DC motor is applied to the solution of an electric screwdriver: the motor adopts a bearing connection, which reduces the wear and tear between the parts, reduces the noise, and prolongs the life of the whole machine. This 6000 rpm 24V high-speed brushless DC motor has the advantages of large torque, low operation, and fast speed. The brushless DC motor does not generate high temperature and toner during use and has better performance, especially suitable for long-term continuous use.

Components of a high-speed brushless DC motor

Basic parts: the armature (rotor), motor front cover, bearing, magnet (stator), and motor gasket.

- Armature: The most important part of the electric batch, like the "heart", the state of the armature will determine whether the electric batch can work normally. The quality of the armature: We can know by measuring its DC resistance. Under normal circumstances, the DC resistance (220V) between the adjacent two poles of the armature commutator is about 15 ohms larger (due to different manufacturers, the value is not the same, the larger DC resistance is more than 20 ohms).

- The front cover of the high-speed brushless DC motor: Judging from the appearance, it is damaged.

- Stator: Judging from the appearance of its internal disk for damage and displacement (causing magnetic asymmetry), at the same time, a flat-blade screwdriver can be placed inside the magnet to check the size of its magnetism. If the magnetism is too small, a new magnet should be replaced.

- Bearing: Judging from the rotating bearing, there is a stuck phenomenon. When the internal friction is strong, the motor crying noise is louder.

- Gasket: Fix the armature to prevent shaking up and down and ensure stability. With the right number of spacers; the armature will not rock up and down, and the armature can be twisted with less force.